Secure your wheels with Rollock

Simple and efficient wheel security that significantly increases road safety!

Minimises the risk of

wheel loss

Money

saving

Drive with

peace of mind

What is

Rollock?

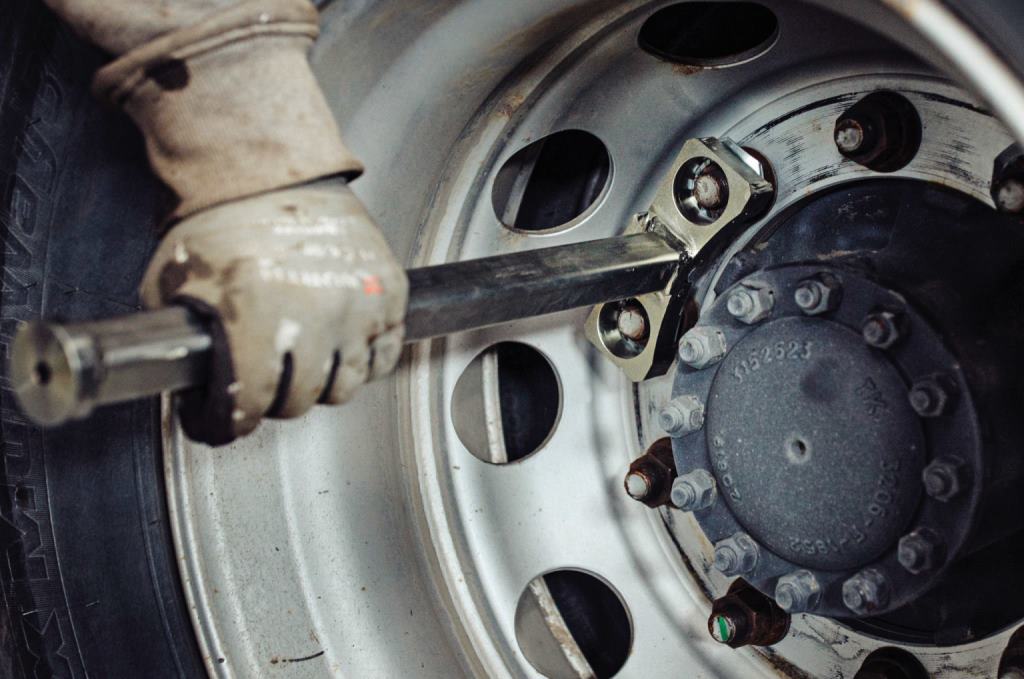

Many truck owners are helpless in finding a solution to make the wheel nuts of their heavy vehicles stay put. Loose lug nuts do not only result in wheels falling off, but also to heavy costs and in some cases to serious accidents.

With Rollock locking clamps the problem is solved.

How does

Rollock work?

Each clamp locks two nuts and is very easy to fit. All you need is our easy to use tool and a plastic-faced hammer. Just drive the locking clamp over two adjacent nuts. The teeth form themselves tightly around the six sides of the nuts and that’s it!

The nuts will remain safely in place, securely locked – minimizing the risk of wheel loss.

The ingenious Rollock leaves no marks and is easy to remove. Unscrew the wheel nut in the normal manner and the clamp will come off easily.

Why Rollock?

What is the cost of a wheel falling off?

- Damage to the Rim, Nuts, Bolts and Hub

- Damaged Tyre

- Damage to Other Chassis-parts

- Lost Time and Interruption (Breakdown)

- Overtime

The costs can easily run to thousands! The worst case scenario is that serious injury or death can result from an accident caused by the wheel coming off.

Available Sizes

Rollock locking clamps are available in the following sizes:

| Rim | No. studs x bolt circle dia. | Nut Size | Rollock clamp |

|---|---|---|---|

| 16″ | 6 x 205mm | 19-21mm | 104 cc 19-21 |

| 17.5″ | 6 x 205mm | 24-27mm | 104 cc 24-27 |

| 17.5″ | 6 x 245mm | 24-27mm | 122 cc 24-27 |

| 17.5″/19.5″ | 10 x 225mm | 30-33mm | 70 cc 30-33 |

| 19.5″ | 8 x 275mm | 30-33mm | 104 cc 30-33 |

| 22.5″ | 10 x 335mm | 30-33mm | 104 cc 30-33 |

| 22.5″ | 10 x 335mm | 32-36mm | 104 cc 32-36 |

| 17.5″ | 10 x 8.75″ | 30-33mm | 70 cc 30-33 |

| 22.5″/24.5″ | 10 x 11.25″ | 30-33mm | 88 cc 30-33 |